Seat materials separating from their structures. Toilets taped together. Lavatories sealed with shabbily rough caulking. That’s not what Cathay Pacific promises with its “Life Well Travelled” slogan, and it’s what the airline would have hoped to have turned its back on last year with its troubled Airbus A350 program, when executives told Runway Girl Network there was a plan in place to fix the situation.

Yet a recent flight on even one of the newer A350-900 aircraft showed the same old problems — in some cases, even worse.

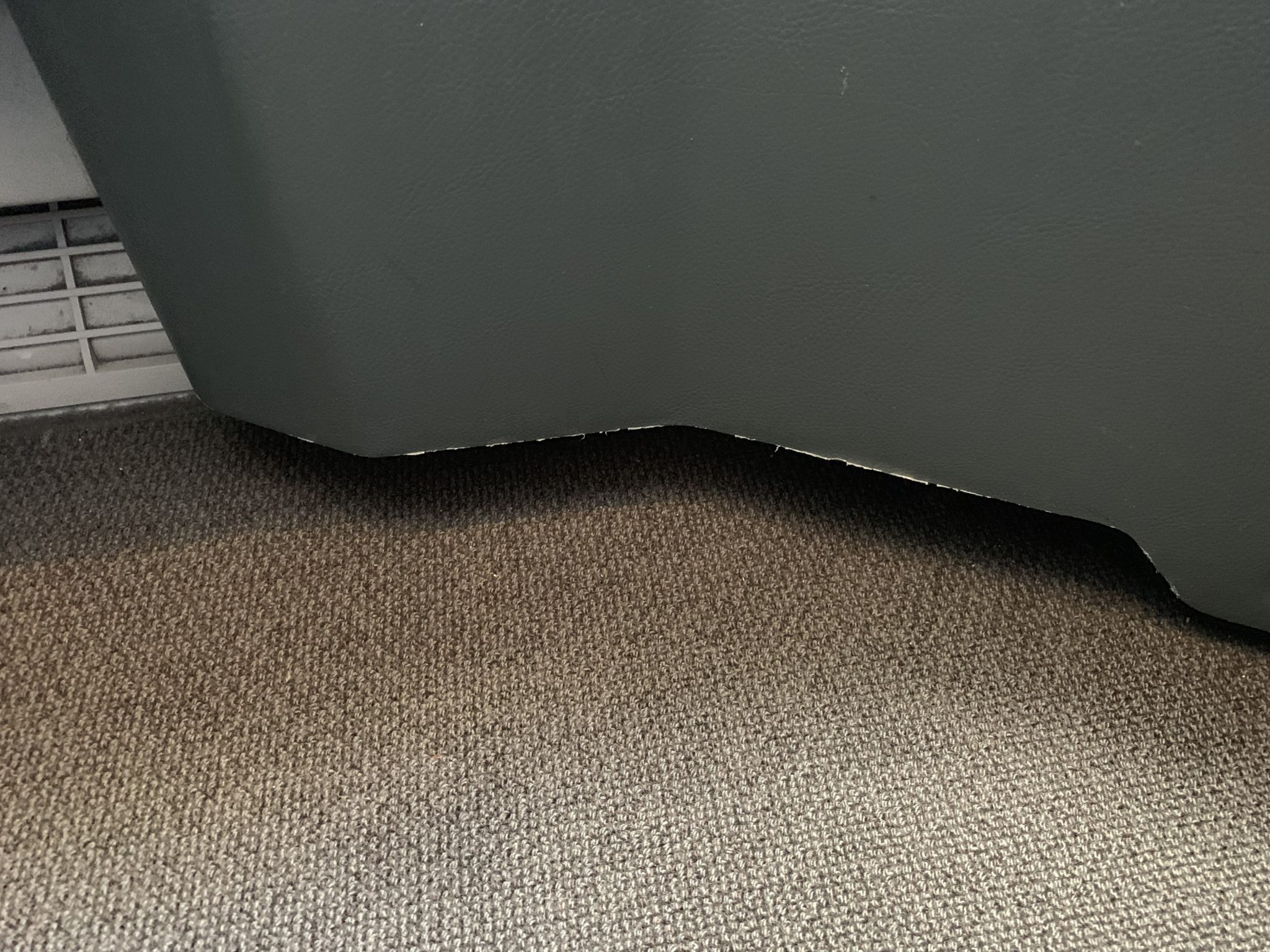

These are not hidden issues. At my seat, the leather shroud in the footwell was separating from the seat shell.

Cathay’s choices in its fit and finish may have contributed to the extent of the problems. Image: John Walton

The side table lamination was peeling away.

The sections of the seat did not line up properly.

The lifejacket compartment was tied to the seat structure.

Sharp edges within the footwell had not been smoothed.

Other seats in the cabin seemed to be in a similar situation.

The lavatories were worse — and RGN checked all the business class ones.

One toilet was literally taped together with what looked like (and seemed to be adhering like) clear packing tape.

In all this journalist’s years of travel, never has a lavatory been in this state. Image: John Walton

Multiple lavatories’ ceiling and walls were secured with the same clear tape.

Caulking was so rough that it looked impossible to sanitize.

Production quality was atrocious, from the doors that didn’t lock properly to the labelling that was wearing away.

This aircraft was B-LRQ, delivered to Cathay in June 2017, months after the airline told RGN that the issues were being fixed. It’s surprising that any long-haul aircraft would be showing quite so much wear and tear after just over a year in service, but this felt like a twenty-year-old aircraft.

Eighteen months ago, Runway Girl Network flew on an earlier Cathay Pacific Airbus A350, and was shocked at the state of the Zodiac Aerospace (now Safran Seats) Cirrus seating product. The following month, Cathay’s general manager product and head of cabin engineering later outlined the airline’s plans to fix the problems to RGN.

It almost beggars belief that these issues remain so evidently ongoing, and it was with some incredulity that RGN raised the issue with Vivian Lo, general manager customer experience and design, at the airline’s Cathay City headquarters the day after the flight (which was provided by Cathay Pacific), showing her the pictures used in this article.

Acknowledging that there were clear issues, Lo said, “what we have done is to ensure we have the right fixes. On top of the fact that those first three aircraft shipsets were completely replaced, we have worked a lot in terms of agreeing what is the right quality and we ensured that those were delivered for the A350-1000 at launch.”

“Given the issues we have had with the A350-900, obviously it was a very — I won’t say painful, but it was a rocky and lengthy experience. What we’ve seen in the last maybe six months of execution of the A350-1000 is that a lot has improved, and they [fixes] are also retroactively being [applied],” Lo explained.

“We’ve fixed that for the A350-1000 at launch, and those changes are now being retroactively launched for the rest of the A350-900 fleet. We have a combination of issues, but for example in terms of the bed extension I think we are about 75% done. Lamination of the surface table is around three-quarters done. The majority of the fixes we should be either completing by the end of this year [2018] or at the latest the second quarter next year.”

Lo was realistic in her response to the images RGN showed her. “In theory we should have critical mass now, so it’s a surprise that we still have that. Obviously it is one of those 25%. We are looking at completion, definitely, by second quarter next year. So we shouldn’t be seeing this. It’s a disappointment for us.”

Cathay’s latest version of the Cirrus seat is more ambitious than some other airlines’. Image: John Walton

For the table laminate, Lo confirmed, “there’s a new material there, and then in terms of the deployment of the back extension and the triangular cushion, we’ve changed the way that it operates. For the armrest it’s slightly slower in terms of progress, there’s a new deployment mechanism. In terms of the recline deployment the system supporting that is also different, so it is basically a lot of work from both teams, including our engineering team, in terms of commanding those changes, but we think we have got an agreed standard that is satisfactory for the -1000.”

The A350-1000, Lo said, is the product Cathay refined, and has been delivered to its design intent. “The main difference is the quality of delivery. The seat design is exactly the same, but at launch we don’t have the same kind of issues with the laminates, with the deployment, the recline et cetera. So far our feedback on the A350-1000 was that those issues were all addressed.”

More widely with the seatmaker, Lo noted, “with Zodiac being a strong — not just a supplier but a partner for us, providing a lot of the premium seats, we have really done a lot in improving that overall partnership, engagement and supplier management program. Obviously they have also gone through a lot of management change, and Safran has taken over. I think they have put in some very solid management that really knows what the key issues are, and they make it their top priority to address them.”

“So far the feedback on the A350-1000 product was substantially better, both in terms of the Zodiac business class seats as well as all the other issues that we have from the lavatory that is more an Airbus issue.”

Calling the lavatory situations on B-LRQ “really one of the worst examples” of the problems, Lo highlighted that Cathay Pacific is dealing with Airbus as the catalogue supplier of lavatories, rather than Safran Cabin (previously, as with the seats, Zodiac Aerospace). Again citing solutions put in place for the A350-1000, Lo said that the updated lavatories are being retroactively reinstalled on the -900 fleet.

This may not go as far as entire lavatories being removed and exchanged, although given the extent of the problems this would not seem overkill. Lo noted that much of the materials making up the surfaces of the lavatories will, however, be replaced, but that supplier constraints are still a problem.

“The progress is not just about whether we have ground time, it’s about how fast the supplier is able to provide those new materials. The pace is really set by Airbus for the lavatories, and Zodiac for the business class seats,” Lo said.

RGN experienced a substantial amount of déja vu during these discussions with Cathay Pacific, as indeed on the flight. Cathay Pacific is not the only airline to be experiencing these problems, either with Safran’s seats or with its Airbus-supplied lavatories.

But as just one recent comparator example, Cathay’s A350s stood in marked contrast on the same trip with Finnair’s, where even RGN’s fine-toothed comb couldn’t throw up any visible problems with the cabin or the seats — also Cirrus, although a less ambitious finish.

Years after these problems were identified on the airline’s first A350’s delivery flight, they are yet to be fully solved. Perhaps the most baffling aspect of the entire situation is that it is still unclear why Cathay Pacific remains unable to do so.

Editorial Disclosure: Cathay Pacific provided the flights referenced in this article.

Related Articles:

- Zodiac to replace three Cathay A350 Cirrus shipsets, fix rest of fleet

- Damaged, substandard Zodiac seats hit Cathay Pacific image

- Cathay first needs a soft product focus and soon a hard product upgrade

- Zodiac talks next-gen Cirrus with ergonomic and storage updates

- Cathay’s 2010-era business seat is solid, but needs changes

- Podcast 044: Laptop bans, Cathay pans, AIX plans

- Zodiac parachutes in new advisor for Safran deal or “standalone” future

- Zodiac to shutter Seats California ops, consolidate with other plants

- Why the six-way headrest on Cathay’s A350 is a tiny revolution