Gen Phoenix has been supplying its ELeather material to the mass transport market, including aviation, for the past 15 years. Now its latest product, a fully circular aircraft seat dress cover, is among the sustainability innovations shortlisted for the 2024 Crystal Cabin Awards.

Gen Phoenix has been supplying its ELeather material to the mass transport market, including aviation, for the past 15 years. Now its latest product, a fully circular aircraft seat dress cover, is among the sustainability innovations shortlisted for the 2024 Crystal Cabin Awards.

Circular in this sense refers to the material’s lifecycle. At the end of its useful life it may be recycled into a brand-new circular dress cover or any other upholstery product employing the same material.

The company will reveal details on 28-30 May at the Aircraft Interiors Expo (AIX) in Hamburg. For now, Nico Den Ouden, chief innovation officer & general manager seating at Gen Phoenix, explains: “So far Gen Phoenix has primarily focused on repurposing the abundance of leather waste that is otherwise sent to landfill. Anticipating increasing demand from brands and consumers for circular materials, we’re excited to reveal progress on adapting our technology platform to accommodate a variety of end-of-life materials, including our own material, at this year’s AIX.

“In collaboration with industry partners Sabeti Wain Aerospace and Doy Design, we’ll also unveil the fully circular dress cover. Currently, all end-of-life seat covers are destined for incineration or landfill, independent of the material used to create them. Our initiative helps solve airline waste issues and reduces seat cover carbon footprints.”

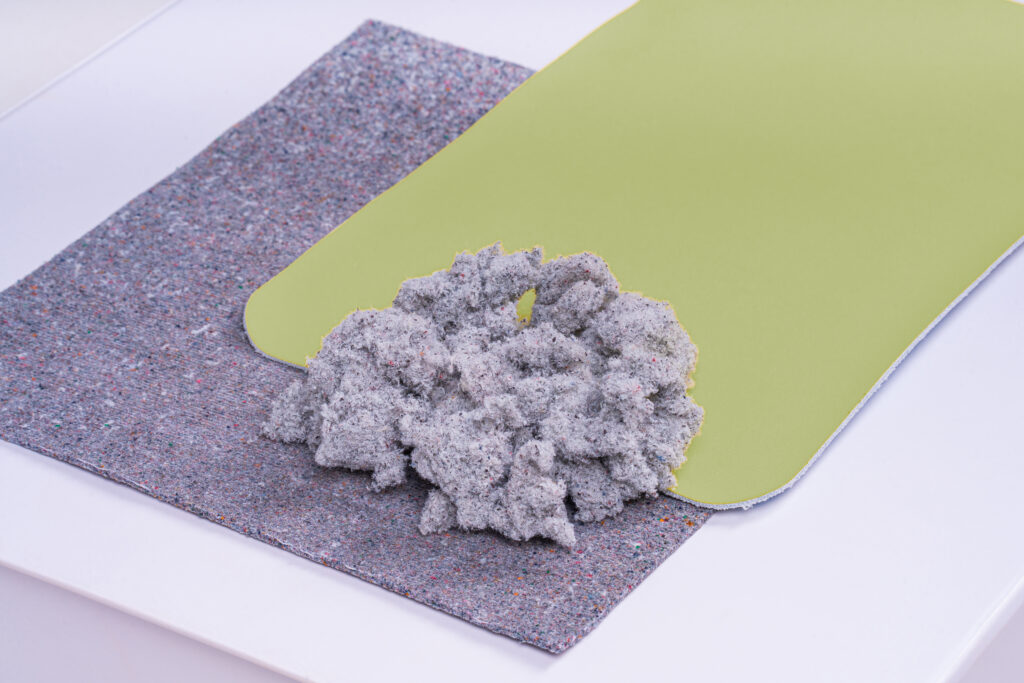

The image at top and here represent the first iteration of Gen Phoenix’s circular aircraft dress cover. The final product — an industry first product in partnership with Sabeti Wain Aerospace and Gary Doy of Doy Design — will be unveiled at AIX 2024. Image: Gen Phoenix

ELeather is manufactured from raw leather hide material discarded by the leather industry and otherwise destined for landfill. The material is processed into fibers, then entangled around a high-performance core using high pressure water. Den Ouden says: “ELeather production uses far less energy and water than are required for traditional leather manufacturing.”

It is also more durable than traditional leather, retaining its pristine appearance up to five times longer according to Gen Phoenix, and equally versatile in terms of color, design, and embossing. In fact, ELeather is a tough act to follow.

To be a truly viable alternative to traditional leather and indeed traditional ELeather, the new product must therefore match the existing product in durability, since even circular materials are less impressive if they need replacing more often than the legacy alternative. It must also offer the same aesthetics and versatility for designers, and compare in cost. Airlines won’t buy it if it’s too expensive and they will also expect weight savings compared to traditional leather, since ELeather is as much as 45% lighter.

Acknowledging the challenge set by its own product, Den Ouden reports: “Our new circular material is engineered to deliver comparable durability and aesthetic appeal to ELeather. We are also striving to maintain cost competitiveness with traditional leather, recognizing the importance of affordability for our customers, particularly airlines.”

Meanwhile, Gen Phoenix’s operational credentials support the sustainability of its product. The company has sent no waste to landfill since 2016, recycles 95% of the water used in manufacturing and runs its production on 100% renewable electricity. Commissioned in 2020, its modern UK manufacturing facility was designed to minimize energy consumption and emissions per unit of product.

End-of-life Gen Phoenix circular dress covers will be the obvious raw material for new product but there is another, even more significant aspect to the material. “Leather waste is one source of feedstock into this circular process, but we can leverage a multitude of other waste types, including textile and plant materials,” adds Den Ouden.

“The material used in the circular dress cover is created from our own end-of-life product, industrial waste, or customer waste reclaimed and recycled again and again through our proprietary technology. We’re looking forward to sharing more details on how the material is made when product is officially unveiled at this year’s Aircraft Interiors Expo.”

Related Articles:

- Perfectly imperfect: Aviation explores beauty of recycled interiors

- How Scottish Leather Group delivers sustainable leather for airlines

- Gen Phoenix looks beyond Eleather for aircraft seat cover recycling

- Designing for sustainability: Soisa studies pecan shells for interiors

- Germany’s BDLI seeks to move the needle on cabin sustainability

- Apple leather? Delving into lower-carbon amenity kits

- Soisa Aircraft Interiors CEO reveals ambitious five-year growth plan

- How SIMONA is embracing sustainability at every rung of its business

- Nature and sustainability inspire ReWILDing collection from Muirhead

Featured image credited to Gen Phoenix