Condor Flugdienst GmbH and Lufthansa Technik AG have signed a contract for the installation of Lufthansa Technik’s newly developed HeatNOW floor heating system in the A320 aircraft fleet.

Condor Flugdienst GmbH and Lufthansa Technik AG have signed a contract for the installation of Lufthansa Technik’s newly developed HeatNOW floor heating system in the A320 aircraft fleet.

Cold spots in aircraft are a well known problem: While the passenger cabin is zone-controlled to comfortable temperatures at outside temperatures of -52 °C, it can get as cold as -10 °C in the galleys during a flight, especially in the lower door areas, due to the sometimes very cold air flow created by the differential pressure.

These conditions not only create an uncomfortable working environment for crew members; other problems can also arise from the potential freezing. In situations where an aircraft is operating in very cold weather, the temperature differences cause condensate to collect on the door seal and mechanical parts, freezing there and potentially preventing the doors from opening easily in icing conditions on the ground.

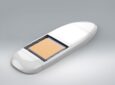

HeatNOW is a heating system based on a patented conductive coating that effectively prevents the formation of cold areas in the aircraft. The heating pad consists of a heating layer between two additional protective layers. Connected to the on-board power, the electrically conductive layer acts as a resistor and heats itself in a self-regulating manner. The power can be regulated in various stages as required. HeatNOW thus provides an even and homogeneous heating of the floor areas.

Conventional solutions, such as standard heated floor panels, not only have high failure rates due to their design, they are also expensive and less efficient, as they can sometimes only be repaired at great expense. The ultra-thin and lightweight HeatNOW system, on the other hand, can be installed easily and flexibly on almost any desired floor panel, in galleys and or in seating areas, and guarantees high performance with great reliability.

HeatNOW is EASA certified for the Airbus A320 and Boeing 737 aircraft family. The certification can easily be extended to other aircraft types. “We chose HeatNOW primarily because the health of our crews is very important to us. With this new heating system, we want to offer our crews a more comfortable workplace and keep them from having to stay in a partly cold working area,” says Christian Schmitt, Chief Operating Office and Accountable of Condor Flugdienst GmbH.

“After having been asked by several airlines to develop a cost-effective alternative for retrofitting a floor heating system in the cockpit and cabin areas, we are now pleased to equip Condor as our first airline customer with HeatNOW. For cargo aircraft operators, HeatNOW is also extremely interesting as an additional floor heating system in the forward galley area between the cockpit and the main cargo bay, where the cargo attendants spend time during the flight. We believe we are providing a great alternative here, either as an additional heating system in already equipped aircraft or as a full retrofit solution,” says Niels Dose, Product Sales Manager at Lufthansa Technik AG.

About Condor Flugdienst GmbH

As Germany’s most popular leisure airline, Condor has been taking its guests to the world’s most beautiful holiday destinations for over 66 years. Every year, more than nine million guests fly with Condor from the nine largest airports in Germany, from Zurich in Switzerland and, from summer 2022, also from Vienna in Austria to around 90 destinations in Europe, Africa and North America. Condor operates a fleet of over 50 aircraft, which are maintained by the company’s own maintenance operation, Condor Technik GmbH, according to the highest safety standards at the Frankfurt and Düsseldorf locations. From autumn 2022, Condor will be the German launch customer for new Airbus A330neo long-haul aircraft. Thanks to state-of-the-art technology and maximum efficiency, the latest generation 2-litre aircraft is the European front-runner with 2.1 litres per passenger per 100 kilometres and the highest level of customer comfort.

About Lufthansa Technik

With more than 35 subsidiaries and affiliates, the Lufthansa Technik Group is one of the leading providers of technical aircraft services in the world. Certified internationally as maintenance, production and design organization, the company has a workforce of more than 20,000 employees. Lufthansa Technik’s portfolio covers the entire range of services for commercial and VIP/special mission aircraft, engines, components and landing gear in the areas of digital fleet support, maintenance, repair, overhaul, modification, completion and conversion as well as the manufacture of innovative cabin products.

Featured image credited to Lufthansa Technik