High above the show floors of this year’s Aircraft Interiors Expo in Hamburg was a conference room filled with representatives from the eighteen-member i+s cabin research partnership, demonstrating how they are working to move aircraft e-enablement, backend Internet of Things communications and connected cabin components beyond the ARINC 853 standard to real-world implementation.

Funded and sponsored by the German Federal Ministry for Economic Affairs and Climate Action, the i+s cabin partners range from Boeing and Airbus through tier 1 suppliers like Safran Cabin and Diehl Aerospace (the consortium leader), together with subsuppliers and academic researchers.

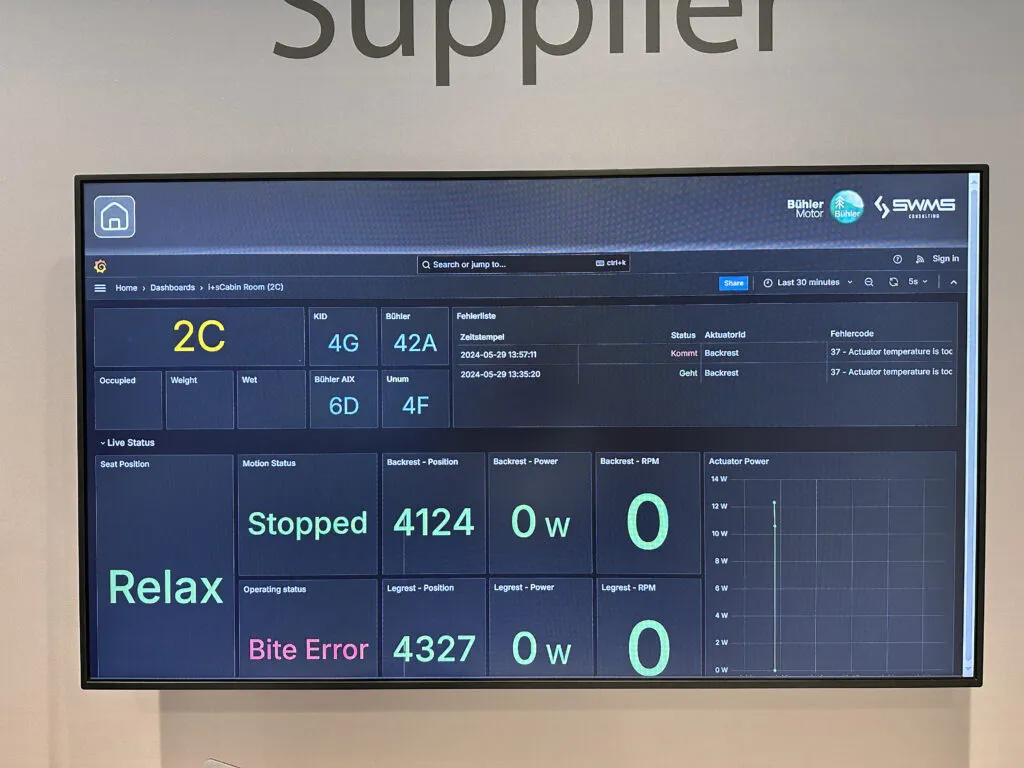

The work is focussing on demonstrating specific use cases: for example, a Bühler Motor actuator on an Unum business class seat on the showfloor several halls away was reporting its status — operational, reclined/upright, and so on — to the main systems display in the i+s cabin conference room. So was an actuator in the room itself, as well as various sensors on various stands.

Bühler Motor’s sensors in the room and on the stand elsewhere were reporting live into the system. Image: John Walton

Lothar Trunk, program manager for innovation at Diehl Aerospace (a joint venture between Diehl Aviation and Thales) tells Runway Girl Network that “one thing we found out is that there is no single gold use case. It’s the overall, it’s working together with data for various applications: that is where the benefits are coming.”

Crucially, much of the work was being done on a platform-independent and supplier-agnostic basis. The plan is for those Bühler Motor actuators to be able to report to a Thales Onboard Data Center, a Boeing on-aircraft system, or any other player within the ecosystem.

Of note for inflight connectivity watchers, even with a drop in per-megabyte data pricing as new communication networks come online, the amount of raw data generated on the aircraft is still prohibitively large for full inflight downloading/uploading.

As a result, on-aircraft processing and on-ground data dumps — via cellular, via gate Wi-Fi connections or even via physical ‘sneakernet’ removal — will be a part of the connected aircraft ecosystem for the foreseeable future.

“When you see the seat application recording currently, and the data you might need for data mining, [for] data scientists for predictive health monitoring, that’s quite a decent amount of data,” Trunk explains. “It doesn’t make sense to have this data transferred via satellite.”

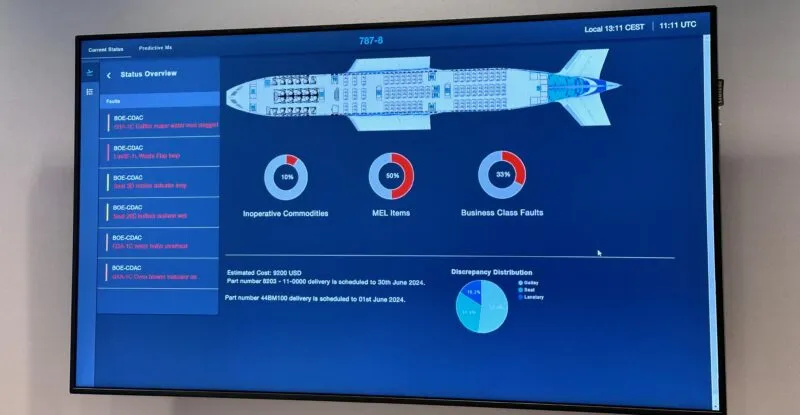

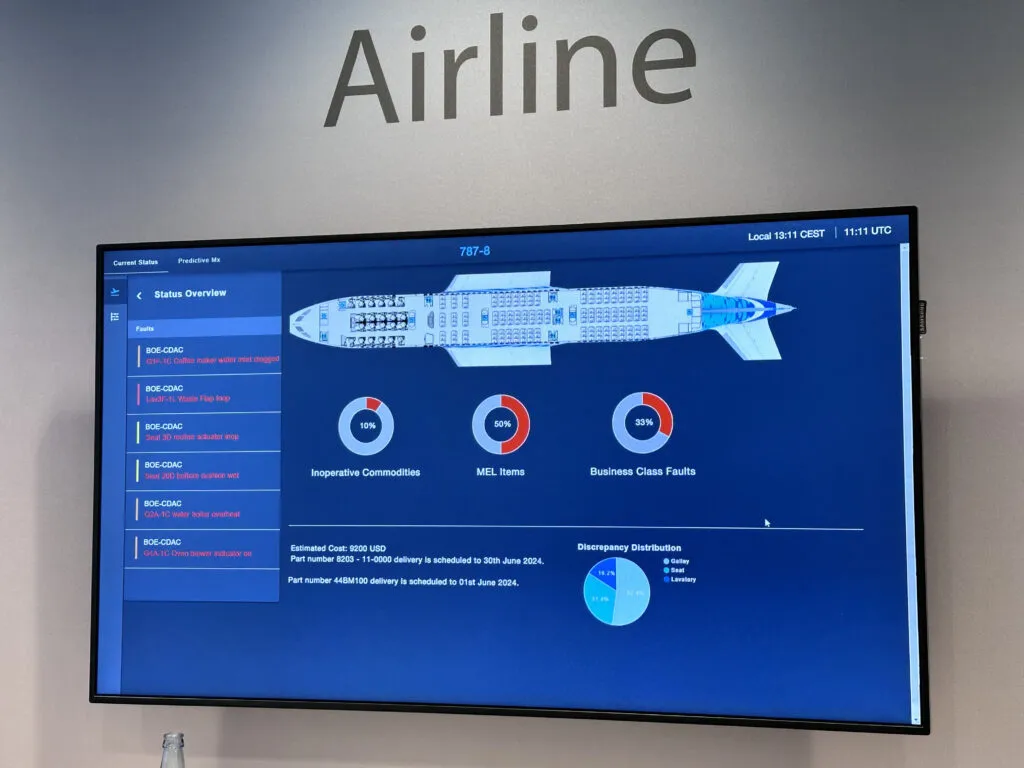

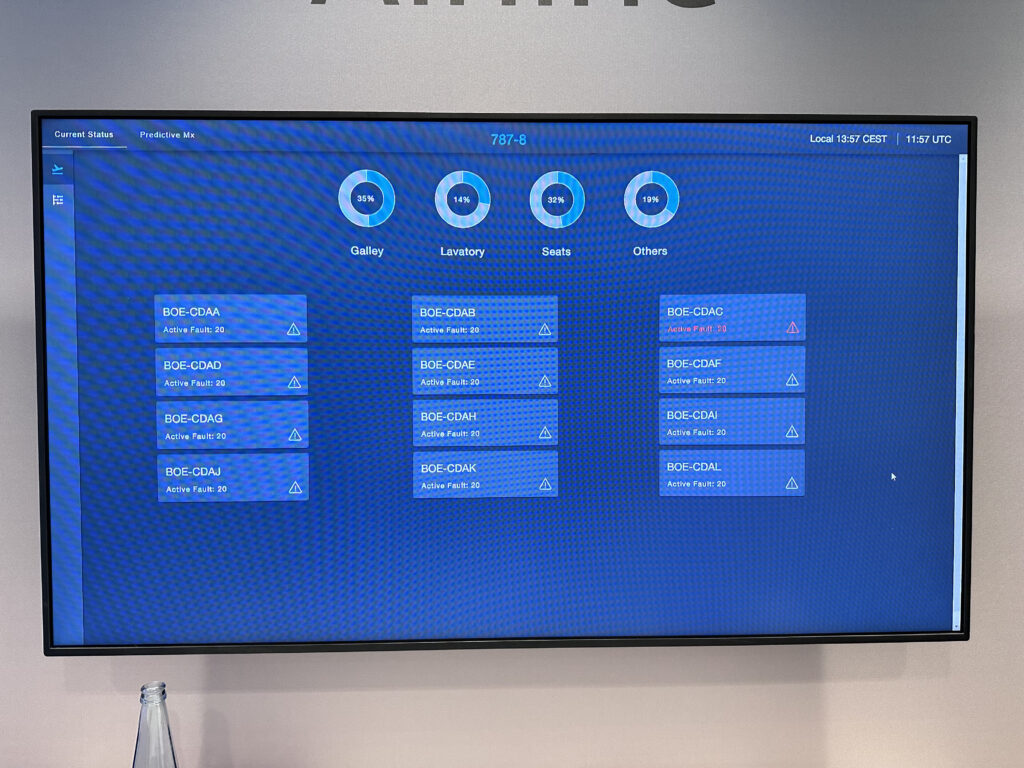

Part of the challenge is creating the dashboards and management information to maximise the benefits of the connected aircraft. Image: John Walton

Pre-processing, especially for exception data — in other words, where a seat’s parameter is anything outside the range of operating normally — is also on the cards.

This opens up not just the one-way ability to (say) report exceptions for immediate maintenance on the ground, but for two-way communications.

As an example, on receiving a maintenance notification, the maintenance engineer (or the system automatically) can request a fuller set of information about a particular seat to be sent inflight.

This allows for earlier diagnosis of the problem and potentially even an inflight resolution recommendation to be sent to the crew if, say, the seat needs resetting in some way.

However, Trunk says, “big data, those raw data, I’m pretty sure will still transfer on-ground, and depending [on] the portions to be transferred on ground, how long the aircraft is on-ground.”

Overall, it is impressive to see so much of the cabin ecosystem working together beyond standards, even those — or particularly those — that would perhaps consider themselves natural competition, like Safran Cabin and Diehl.

“We do have 18 partners in the team,” Trunk notes. Adient Aerospace, Jeppesen, German university TU Hamburg, and foam company Neveon are among them.

“Even [as] competitors, we need this minimum to make this movement in the industry,” Trunk concludes.

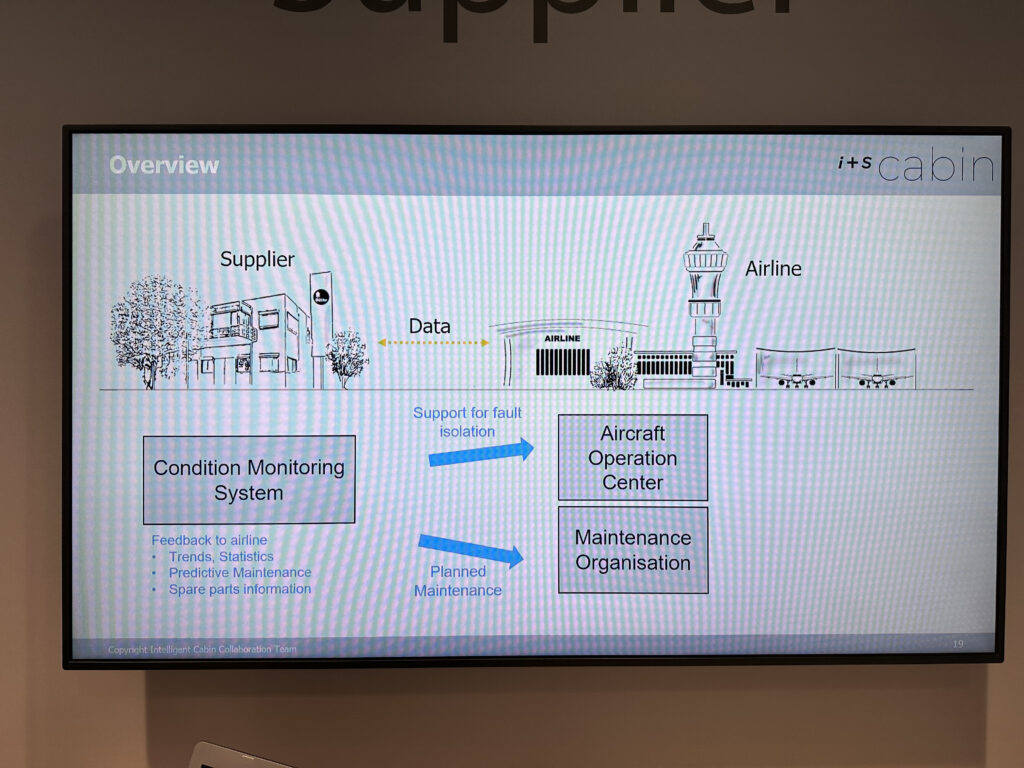

i+s cabin feedback for airlines includes trends, statistics, predictive maintenance and spare parts information. Image: John Walton

Related Articles:

- Diehl and Thales work to unlock the full potential of cabin data

- IATA partners with Aviation Sustainability Forum to tackle cabin waste

- Airbus lays out ultimate vision for connected aircraft

- Thales takes IFE innovation to the edge with edge-caching and the cloud

- Collins makes Cabin IoT play with connected galley field trials

- Covarians seeks to improve cabin environment through actionable data

Featured image credited to John Walton