John Walton: Hello, and welcome to Runway Girl Network in Conversation, a deep dive into aviation and the passenger experience. I’m RGN deputy editor John Walton, and today I’m in conversation with Zuzana Hrnkova, Vice President and Head of Marketing at the airframer ATR.

John Walton: Hello, and welcome to Runway Girl Network in Conversation, a deep dive into aviation and the passenger experience. I’m RGN deputy editor John Walton, and today I’m in conversation with Zuzana Hrnkova, Vice President and Head of Marketing at the airframer ATR.

Walton: But first, thanks to our sponsor. In Conversation is brought to you by Boltaron, a SIMONA company, purveyor of high-performance thermoplastics for tomorrow’s aircraft interiors. With new and groundbreaking innovations in design capabilities, Boltaron offers airlines the ability to customize the cabin, with lightweight materials with metallic effects, translucent decorative panels with unique embedded patterns, dynamic textures, vibrant pearlescents and much more. Learn more at boltaron.com.

Walton: Now, Zuzana, welcome to In Conversation.

Zuzana Hrnkova: Hello, John. I am really delighted to have the opportunity to share with Runway Girl.

Walton: It’s wonderful to talk to you again. Zuzana, for those who aren’t familiar, would you give us a quick pencil sketch of ATR, what it is and what its product line is?

Hrnkova: ATR is a Franco-Italian regional aircraft manufacturer. The company is based on the equal partnership between two aviation industry leaders, Airbus and Leonardo. We are producing the best-selling regional aircraft, best-selling in the last decade, and the ingredient for success is that we have a family of two aircraft. ATR 42, which is a 50-seater aircraft, great route opener. And the ATR 72, so the larger model with 70 seats, however we have a 78 seat capability for high capacity configuration. It’s a great product which represents 35% of the market share of the regional aircraft in the 50 to 90 seat category, including turboprop and the regional jets.

Walton: Wow, that’s an impressive market share. Tell us about how the company benefits from having these two model aircraft. Obviously, your competitor, which is of course now de Havilland Canada, doesn’t currently offer anything smaller than the Q400 which is a 74-seater competitor to the ATR 72.

Hrnkova: As I said, the advantage for having a family is that with a small model, the ATR 42, the airline can explore new market potential. And then, compete with the larger capacity aircraft, when the traffic grows here, traffic demand is here. So I don’t know if you know, John, but the airlines around the world… So we have 200 operators, 200 customers, across the world, in 100 countries. Those operators open every year more than 100 new routes with the ATR products.

Walton: That’s an impressive statistic.

Hrnkova: And you know that 58% of current turboprop regional network, did not exist 15 years ago. And we have forecasted that 30% of the future traffic in the upcoming 20 years is going to come from the routes which do not exist today, and we believe that the ATR is going to play a crucial role here.

Walton: So what are these routes, as some examples? Is it point-to-point flying? Is it connecting people from regional sub-centres into regional hubs and then onto larger hubs? What’s the profiles there?

Hrnkova: So they are both. Our airplane is playing a role on both areas, depends on the region. However, more and more we see that the ATR 42 could be a great tool on point-to-point operations, especially on very remote areas or challenging airports, and can really enhance and help local economies to grow.

Walton: Okay, I see. So how far can you fly in an ATR, in terms of nautical miles and then in terms of flight duration?

Hrnkova: So for a regional segment, the max range capability is not an issue. I would rather say about the average sector and the segment where the turboprop aircraft is doing the best job. So the average segment for our operators is around one hour, so around 250 to 300 nautical miles.

Hrnkova: However, we have operators flying from less than ten minutes between two islands, up to three and a half hours. And, by the way, it’s one operator doing those two types of operations.

Hrnkova: And then to maybe answer more precisely to your question, we have an ETOPS capability for up to four hours.

Walton: Wow, up to four hours of range away from an airport, that’s pretty impressive. What sort of profile is that? Is that one that’s connecting to a hub? Is that connecting to a remote island?

Hrnkova: This is rather type of operation connecting remote islands and remote areas.

Walton: Okay. So, in terms of the rest of the market, both in terms of a lot of the legacy turboprops and then of course the Q400, what makes the ATR different? What’s the unique selling point?

Hrnkova: I would start definitely by the great accessibility to the airport. I already mentioned the accessibility to challenging airports, as well as the airports with very few ground equipment. We have operations on the very extreme meteorological conditions, very hot temperatures or very cold temperatures, as well as we can operate on runways only 14 meters [wide].

Hrnkova: Then another differentiator is definitely the advanced technology. So we have a glass cockpit, and advanced performance-based navigation capabilities. And maybe one equipment which is unique in commercial aviation, I have to mention Clearvision. So it’s equipment which allows the operations in low-visibility conditions.

Hrnkova: And then a very important one is links with operating economics. Very simple architecture of our aircraft, and then turboprop propulsion technology are resulting in very competitive operating costs and the airlines really appreciate this part. And the part of the turboprop technology is linked as well with the very low fuel consumption.

Hrnkova: John, I don’t know if you’re aware, but our aircraft is burning 40% fuel less compared to equivalent jet aircraft, and by consequence produce 40% less CO2 emissions. And then it’s very quiet [for the] neighborhood, because the external noise produced by our aircraft is 9 decibels below ICAO chapter 14, which will be introduced from 2020, from next year. So already our aircraft is future-proofed in terms of external noise. And it’s 13 decibels quieter compared to regional jet aircraft.

Walton: Yeah, I mean, that’s interesting. I think a lot of people have this idea that turboprops are noisier, but that’s because they’re probably thinking of it from inside the cabin. Whereas actually, from outside the cabin and for neighbors of airports, that’s a real benefit.

Walton: In terms of how turboprops are constructed, the idea of having the exposed fan blades, why does that make it more efficient? And why is there a lower impact on the environment than, say, a modern regional jet?

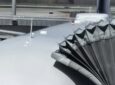

Hrnkova: As I said, this is thanks to the turboprop technology. Just to give you an insight, the turboprop engine inside of the engine works like a jet engine. So in terms of technology it’s comparable, which means it’s the latest technology, latest material is used. So the air is compressed into the engine and it’s mixed with the fuel and ignites the mixture. The resulting force rotates the shaft which, in turn, drives the propellor, accelerating the flow of air to create the thrust that makes the aircraft move forward.

Hrnkova: And the turboprop, thanks to that, is more efficient on short sectors because the air is accelerating using less power, thanks to the propellor, which has resulted in less fuel consumption. So, for short flights of about one hour, during which you don’t have time to reach high altitude or high speed, the fuel consumption could be nearly half of a similar jet size aircraft.

Walton: I see. Because, of course, turboprops have a lower operational ceiling, so is it that you’re at your optimized level faster and for longer, for a shorter flight? Is that part of how it works?

Hrnkova: It’s more resulted in the fuel efficiency. The low flying altitude could bring something additional to the passenger experience, which is very nice views through the window. So we can talk about a native in-flight entertainment.

Walton: Well, exactly. I remember when I used to live in New Zealand, flying down from Wellington to Queenstown right over the Southern Alps was just one of the most beautiful views. You certainly didn’t need a screen for that, I tell you.

Walton: Now, thinking about the operational side of the aircraft. Obviously the ATR has relatively good runway performance, right? It needs a relatively short runway. But at the Paris Air Show, you introduced something new, the short takeoff and landing ATR 42-600S.

Walton: Tell us a little bit more about that, please, and why it’s needed.

Hrnkova: Maybe a couple of numbers. So, as I mentioned already today, ATR 42 take off and landing capability and airport accessibility is very good. Now the max takeoff distance is around 1,100 meters.

Hrnkova: However, we see that there is around 1,200 aging turboprop aircraft in the 30 to 50 seat category which will need replacement in upcoming years, and inside of those 1,200 aircraft there is one part which today perform takeoff and landing on the runways between 800 to 1,000 meters. So on top of that, we have around 460 airports around the world with runways below 1,000 meters, so between 800 and 1,000 meters, which are not operated on scheduled service today.

Hrnkova: And we have a lot of requests from airlines or even from governments, because they are willing to develop the activity in such areas. So this is why we have decided to work on improving the takeoff and landing capability of the ATR 42 and bring the great solution to address this replacement market.

Hrnkova: And also to address new market potential for a new development. And, John, there is a lot of places around the world which are located in natural heritage sites and the governments are willing to develop the activity, so there is no possibility to extend the runway because they want to protect the nature around, and this is why they are interested in the ATR 42S with this improved takeoff and landing capability.

Hrnkova: So the new aircraft will be able to takeoff and land on 800 meters [of] runway with the payload equivalent to a 30-seat turboprop, and they will need around 900 meters to perform the full payload with 50 passengers on board. So that will be a great tool to address replacement market as well as the new market, and help development of local economies.

Walton: I see, you can do 30 passengers at 800 meters or full capacity at 900 meters, is that it?

Hrnkova: Yes.

Walton: Interesting. Technically, what’s different with the 42S to a regular old 42?

Hrnkova: So basically there is very few changes. To be capable to operate or takeoff from shorter runways, you would need more controllability so this results in a higher rudder. So we are going to increase the rudder slightly. Then, to perform the landing as well on shorter runways, you would need to have a modification on brakes, so we are going to introduce the autobrakes. And then there will be, by consequence, some modification on the avionic in the cockpit. Then we are going to use the thrust of the engine of the ATR 72. So that’s basically the difference compared to existing 42.

Walton: I see. Interesting stuff.

Walton: In terms of this replacement market, what are the aircraft that are currently operating these routes, and what sort of routes are they? I assume, given that the launch customer is supposed to be Air Tahiti, that it’s going to be a little bit of island hopping in the Pacific. But what else is there? Is there some sort of opportunity around rural and remote airstrips, that kind of thing? Perhaps in Australia for the fly-in, fly-out market? Tell us a bit more about that please.

Hrnkova: Based on current operations on STOL airports we see that there is an opportunity in Canada. Then opportunity in northern Europe. We see opportunity, of course, in Asia Pacific on islands, even in Japan.

Hrnkova: And maybe one point which is important to mention, that we are still waiting for the board approval to launch this product. However, based on the performance from Le Bourget Air Show, we are working on it and we believe that we will receive the board approval in upcoming months.

Walton: Fantastic. What was the reaction at Le Bourget? Did you have airlines lining up round the stand?

Hrnkova: You have seen a couple of announcements from the press, with the customers who are committed to the ATR 42STOL. Of course, we have received a lot of visitors during Le Bourget Air Show who wanted to learn more about our innovations in general.

Walton: Interesting stuff. It’ll be interesting to see indeed whether the board approves it. Now, talking about passenger experience, which is of course our thing at Runway Girl Network… Obviously as a rule, turboprops tend to be a little bit smaller in fuselage diameter than jets. Not necessarily that dissimilar from your smallest type of regional jet, but compared with an Embraer or anything larger than that, they are a bit smaller. And one of the criticisms has been that the seats have been a bit narrower, but I know that ATR has been doing a bit of work on that. Tell us about that work. How are you improving the passenger experience within the turboprop sphere?

Hrnkova: This perception that the ATR cabin is narrower compared to regional jet deserves some clarification indeed. Do you know, John, that the ATR cabin is that largest cabin in the turboprop segment? It’s even larger compared to some regional jets. However, it’s offering equivalent comfort and passenger experience to larger jets.

Hrnkova: So, how we have achieved that?

Hrnkova: Well, in terms of interiors, first in 2011 we have introduced the Armonia cabin. So, redesigned completely the interior, offering more integrated design with the similar design language, redesigned passenger service unit using the light source and light technology. So we have replaced the fluorescent tube lighting with LED lighting, as well as added new sources of light in the cabin with indirect light. As well, we have also introduced this mood color light on reading lights and passenger service units.

Hrnkova: And then the second big improvement was related to overhead storage compartments. We have really optimized the space in overhead storage compartments. First of all, with the contemporary design, the cabin looks lighter and brighter compared to the previous generation.

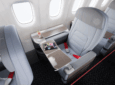

Hrnkova: And then in 2016, we have started to work on the new seat as well as we did approach on optimized use of upper cabin width because, as I said, we have the largest cabin in the turboprop market.

Hrnkova: And from 2018, we have brought on board brand new seats, Neo Classic and Neo Prestige, which is offering 18 inches passenger comfort, 18 inches width between arm rests. As well, the seat is lighter, more ergonomic, and the passenger feeling on this wider and ergonomic seat is that at an equivalent seat pitch they feel like they gain two additional inches for leg room. So they feel they have more personal comfort. And I believe, John, you have tested the seat and our aircraft interiors, and maybe you can as well testimony?

Walton: Yeah. Both at aircraft interiors and the Geven factory near Naples. I found it really interesting. I think that I, and a lot of people, were surprised and somewhat skeptical of the 18 inch claim. And obviously, a good part of that is that you’ve narrowed the arm rests quite significantly. So are those arm rests holding up in service? How many of these 18 inch seats have been chosen? How many are operating these days?

Hrnkova: The 18 inch seat has been developed together with our customers. We have used the mockup and invited a huge number of operators or customers and now the seat becomes a new standard. So every single ATR which is produced from 2018, mid-2018, so from roughly summer last year, is equipped with Neo Classic or Neo Prestige. What we have observed, roughly 80% of customers are selecting for entire cabin the Neo Prestige seat. So this Neo Prestige seat has a recline and some additional features. And then the rest of the customers are selecting a mix between Prestige and Neo Classic or full Neo Classic configuration.

Walton: Why would they be selecting a difference between that? Is it, sort of, premium economy version up front, three or four rows? How does that work?

Hrnkova: There is around 20% of customers who differentiate, a two-class layout. It’s a half-half between using the Neo Prestige in front with a higher pitch and then Neo Classic as economy. Or they just differentiate a couple of rows with additional pitch on Neo Prestige and use it like a business class, and then the rest of the cabin economy class.

Hrnkova: And what is maybe interesting to mention is that when we had this Neo Prestige across the entire cabin, we are offering on ATR, on regional aircraft, much more higher comfort compared to what you can have on equivalent sector with larger jets like single aisle aircraft, because of recline and leather and additional comfort features.

Walton: Recline is really interesting, because there are a lot of us who, for flights that are around an hour or so, really wonder whether or not someone does need to recline. Or whether it makes more sense to install something like a pre-reclined seat so that everyone has a little more comfort to begin with. What’s your take on that? Is recline still in demand from airlines and passengers?

Hrnkova: Maybe to explain a little bit more, the Neo Prestige has a recline, Neo Classic has a pre-recline, so a fixed back shell but with a pre-recline. And based on our statistics, what we are delivering, we see that there is still a majority of customers who are willing to offer more passenger experience with the reclinable seat.

Walton: Going back slightly to the overhead bins, how have they been improved? Do you have a clamshell? Is it that you’ve managed to scoop out some more space into the ceiling? What does that involve?

Hrnkova: We have done several improvements on the overhead storage compartments. First of all, our overhead storage compartment is the fixed box. And we have improved the stowability of the box by removing the hinge which was the case on the previous design, which means that we have really optimized usable space inside of the bin, which results in the possibility to store two very large roller case, roll-on bag, 18 inches wide bag.

Hrnkova: And then the second improvement is that the bin door is sliding over the bin. So it’s completely hidden when the bin is open during the boarding phase, which means for tall passengers it’s an incredible improvement in terms of standing comfort because there is no door intruding [into] the aisle. So, 20% more storage space and then the improvement of the boarding comfort.

Walton: You know, I certainly noticed the different sizes of bins when I walked round the new Armonia cabins. And yeah, it’s an interesting change. Are you seeing that airlines are doing less of the gate checking of bags in this case?

Hrnkova: The handling of the luggage is more in airline world, airline business, but definitely the passengers appreciate the additional storage space and probably all of us as traveling people with our passenger experience, we appreciate the space and possibility to bring a cabin bag. So definitely operators with the Armonia cabin will allow to bring on board larger passenger cabin bags.

Walton: Interesting stuff.

Walton: At the Aircraft Interiors Expo in April, you were showing off this really interesting concept for Deaf and hard of hearing passengers, around an induction loop. What did that involve and how did you get involved with that?

Hrnkova: The Audioback, the hearing loop, we have continued showcasing it at Le Bourget Air Show with the additional visitors, additional airlines, and this experience has helped us to definitely endorse the market interest. We have also understood that today the airlines don’t really treat… They have no appropriate solution to hard of hearing passengers, which means that there is a big market interest. And internally, in ATR, we are working very closely with engineering to integrate the system in our aircraft which means that the tool, the hardware, will be integrated in the seat headrest. So it will remain loose equipment, however there is a part of the equipment which needs to be integrated to the cabin management system for the cabin PA announcements. So there is a little part of the system which needs to be integrated in our aircraft. So we are on it and plan to get the first customers for the system next year.

Walton: Interesting.

Walton: And in terms of practicalities… So, it’ll be inside every headrest? Or will you put an additional extra headrest cover on for people who are deaf or hard of hearing?

Hrnkova: Based on the airline feedback, what the airlines would prefer to have a couple of loose equipment, so not equip every single headrest. However, to have two or three available in the cabin and this will give them the flexibility to locate hard of hearing passengers anywhere in the cabin.

Walton: Right. Then, of course, people who have hearing aids or other auditory equipment, they just turn the setting to the T setting, which we may all be familiar with from movie theaters and other sorts of public spaces, right? Is that how that works?

Hrnkova: That’s exactly how it works.

Walton: Fantastic. It was great to see that working, and indeed to talk to you and a member of the Deaf community about that. That was absolutely fascinating stuff.

Walton: So, looking to the future, Zuzana. What’s next for ATR? We talked a little bit about the 42S, the short takeoff and landing version. I think a lot of people are wondering, in the age of people looking to more ecological and environmentally friendly solutions, larger turboprops or even electric turboprops. What’s on the horizon?

Hrnkova: What we see as a trend is rather trend to smaller capacity aircraft. As I mentioned, there is a great opportunity to replace aging 30 to 50 seat turboprop aircraft. So I mentioned, around 1,200 aircraft for upcoming years. So that’s the first point. I believe as the trend is rather in smaller capacity aircraft, it’s not time to go for the larger capacity. We have already the ATR 72 which is offering capacity up to 78 seats. So we will see how this configuration is going to evolve and will be endorsed by the market. For the time being, it’s rather positioned on the low-cost market.

Hrnkova: And then, of course, we are monitoring evolution of technology because we see that the environmental dimension becomes very important, and already other aircraft with environmental footprint which is very well-positioned, I would say it’s leading in the regional segment. It’s definitely well-positioned to be the great benchmark or starting point for the future technology integration.

Walton: Once we have an electric type engine, I assume that it would be relatively simple to simply replace the aircraft engines that are already on the ATR with something like that, would it? Or is it much more complicated than that?

Hrnkova: Of course it’s much more complicated. It’s not only plug and play question, and there is several domains we can have a look [into].

Hrnkova: First of all, the maturity of technology. When we are talking about new technology and we talk only about the electric, we see that the technology in terms of battery storage is not obvious enough. Just to give you a flavor, to make a takeoff of our 42 with 18 ton max takeoff weight, we would need the same weight of the battery to make it happen. So this is not realistic.

Hrnkova: We believe rather in sort of hybrid utilization. When you use the electric power for one phase of a flight, for example for the cruise time, or additional electrical power for takeoff but it will be mixed with the thermal technology power.

Hrnkova: But you know, John, for me, what we really need to look at is the adaptation to the entire ecosystem. I don’t know how familiar you are with electric cars or hybrid cars. I have a little experience, I’m selecting my new car, and I’m targeting to go for hybrid. And what I discovered is that even with the power cable, it’s hell. So, first of all, you have to put the installation at your home, and then there is no standardization in the cable so I see that I have to purchase two cables to be able to plug, for example, at home, at work or somewhere downtown. And this will be same for the aircraft.

Hrnkova: So what we need to think at the same time as the technology is evolving, is how to adapt the airport infrastructure. How we are going to bring the source of energy, if it’s not electric, but if we talk about the fuel cell, hydrogen or these kinds of sources, how will it be transported to the airport?

Hrnkova: So I think what we need to focus on as well is how we are going to integrate this new technology to the ecosystem of our operators. And this is why we, ATR, as an airframe manufacturer, we have signed an agreement last year with Air New Zealand to have a look on this side, what does it mean, the new technology in the ecosystem and in the logistics of one operator? So there is not only the technology of the power system, but as well how we adapt this new technology to the regional aircraft ecosystem.

Walton: Yeah. It’ll be really interesting to see what the results are of that study. I’m really encouraged, from an environmental point of view, that there are so many people and so many companies who are really starting to look more carefully into this. So it’ll be interesting to see what happens.

Walton: I think that’s it for today’s conversation. We certainly hope you enjoyed it, listeners. And we’re always keen to find out what you think. Please feel free to e-mail me at john@runwaygirlnetwork.com with any suggestions.

Walton: Thank you to our guest, Zuzana Hrnkova. Zuzana, where can people continue the conversation with ATR online?

Hrnkova: You can follow ATR adventure on Twitter or Instagram, @ATRaircraft, or on our website at atr-aircraft.com, or atr-intolife.com. Of course, you can also follow us on LinkedIn.

Walton: Great. And, as ever, you can find me on Twitter @thatjohn and everything from RGN on Twitter @runwaygirl and at runwaygirlnetwork.com. If you’re enjoying these conversations, please leave a rating and review wherever you get your podcasts. And thanks for listening.